Half a century of innovation

Final part of the Ping story

IN THE 1970s company founder Karsten Solheim perfected his patented loft and lie gauge and developed a unique colour code system for custom-fitting and custom-building its cast irons for its customers. He identified that because golfers are not all the same height, he could colour-code clubs to suit the tall, the average and the short to help them hit the ball straighter and enjoy the game more. | |

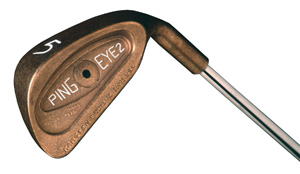

It was another Solheim innovation that challenged a golf industry to follow along its footsteps and today there's a huge movement towards having clubs tailor-made to a golfer's personal specifications, rather than merely purchased 'off the shelf' based on brand or design preference. The decade of the 1970s also saw Solheim develop 'Ping Man', a robot which simulated the human golf swing with wrist-cock and shoulder turn. He used it for research and development to improve his golf clubs and combining it with ultra high-speed cameras, unlocked secrets of the golf swing and later captured invaluable photos of golf club-ball contact at millions of frames per second. The result was the birth in the 1980s of arguably the most successful Ping iron - the Eye2 - which, in its heyday, was played by millions of golfers and became the subject of the “Great grooves debate” when the USGA declared the club did not conform to the Rules of Golf. A lawsuit ensued, and an out-of-court settlement was reached in 1990. Confirmation that the Ping Eye2 was the golfers’ club of choice occurred when readers of Golf Digest, the top-selling golf magazine in the US voted a set of the clubs be placed in the USGA's 100th anniversary time capsule along with other golf memorabilia. Emerging at Solheim Sr's side at this time was son John, who became the company’s president in 1995 and assumed the Chairman and CEO role in 1999. He introduce the Ping ISi iron, produced for the first time in a nickel alloy for softer feel. It was followed by the Cushin shaft insert to reduce shaft vibration. | |

Solheim Jr also focussed his creative thinking to the development of the industry's largest custom-fit driver. The Ping TiSI, featured distance control, combining ISI technology with titanium. Today, the company’s popular G Series (G2, G5, G10) and Rapture Series drivers are among the highest performing and top-selling drivers on the market. and also include irons, fairway woods and hybrids. Other Ping innovations during their 50 years include:

In 1969, Solheim Sr pioneered investment casting to improve quality and ensure consistency of Ping products.

By distributing the weight to the extremities of a club, Solheim Sr was among the first to increase the size of the sweetspot and reduce twisting from off-centre hits.

Moving the weight from the centre of the putter to the heel and toe, created better putter head balance and less twisting from miss-hits.

Putters and irons are subjected to intense heat in vacuum furnaces to make the metal more malleable and permitting easier loft and lie adjustment.

Prior to Solheim Sr applying his engineering theories to club design, most putters were either blade or mallet types. Cavity back putter design originated with Ping and created a giant leap forward.

The first Solheim Sr putter - the 1-A, for which a patent was filed March 23, 1959 and granted three years later - made a distinctive P-I-NNNNNN-G sound from which the brand name was born.

Golf's most popular putter was created in 1966 and to date has more than 600 professional Tour wins. The Anser hosel helps golfers set their hands in the proper putting position and is a much-emulated design.

A measurement system developed by Ping to establish the correct lie angle of an iron to suit a specific golfer. A loft and lie gauge has also been patented to manually adjust Ping irons for precision loft and lie calibrated to match others in every set.

Ping pioneered the modern U-shaped or square grooves when revolutionary Ping Eye2 irons were introduced them in 1982. Later C-5, C-6, C-7, C-8, C-9 swingweights were introduced for custom-fit irons with lighter swingweights to help make golf easier for all golfers.

In 1985, Ping introduced the opportunity to perfect a new shot-saving club - a 60-degree club to enable golfers to play a high-soft-landing 'parachute shot.'

All Ping irons have individual serial numbers used to register the specifications of each club with the company. The numbers are stored on computer to replace any lost, stolen or damaged iron with an identical replica. Ping also cast the company name and address (including zipcode/postcode) into the cavity of its putters and later its irons reasoning that 'word of mouth' advertising was vital, especially when a golfer hit a good shot. | |

Exotic alloys Ping clubs were the first to be manufactured with such high-tech manganese bronze, beryllium copper and beryllium nickel.

In 1998, John Solheim developed the TiSI driver -- the largest custom-fit, custom-built driver in the industry at the time--featuring more distance, control and customization with several unique advances in driver design.

Selective filtering with a cushin insert into golf shafts, was a significant leap forward in golf technology. Based on vibration frequencies it improves the feel of Ping irons.

The most successful lightweight stand bag in the industry was designed by John Solheim. Originally called the L-8, it has evolved into the L-8+ and The Hoofer and continues to dominate the junior and collegiate ranks. The Solheim Cup The Solheim family created a series of matches for professional women golfers between the US and Europe in 1990 modeled on the men’s Ryder Cup with singles, foursomes and fourball matchplay.

Ping wanted golfers to see how far their clubs were being hit, so they put numbers visibly on the back of irons and later added them to the upper toe on the clubface so golfers could verify their club choice at address, without having to look at the bottom of the club. They also devised a pick-up flange on the back of their putter to help golfers pick up the ball more easily. |

Sponsored Posts

Latest News